Shaker doors are everywhere in today’s design world, but confusion often arises when molded shaker versions enter the picture. Many builders struggle to explain the true difference. If you’re sourcing doors or advising clients, this guide breaks it down clearly — saving money and making smart design decisions easier.

Now let’s explore the key construction details, visual differences, and when to choose one over the other — especially if you’re supplying or installing at scale.

What Is an Imitation Shaker Molded Door?

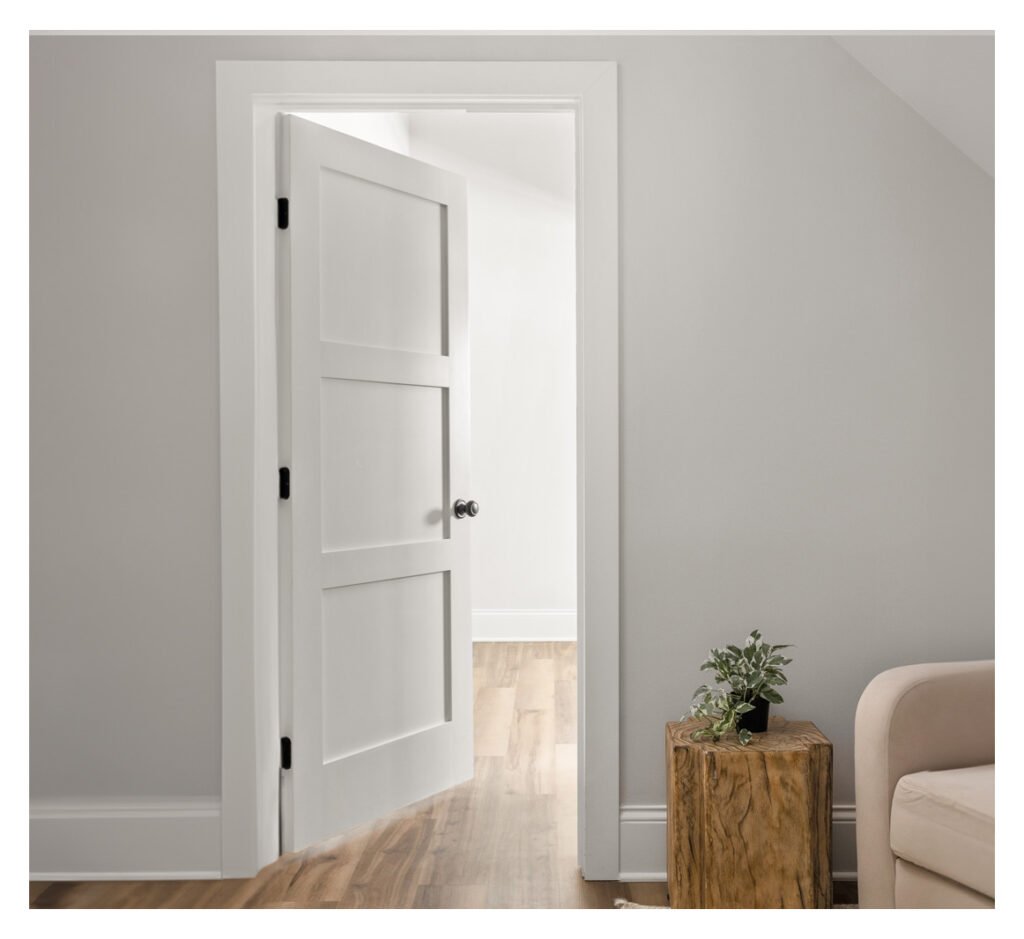

An imitation Shaker molded door is a type of molded interior door that replicates the look of a traditional Shaker-style door, but it is made using molded MDF skins instead of real wood or routed MDF panels.

- Lightweight and affordable

- Panels are molded with soft bevel edges, not sharp like real Shaker doors

- Pre-primed or prefinished, reducing on-site work

Ideal for: Large-scale residential projects, apartment units, or budget-conscious builds.

What Is a Molded Door?

A molded door is constructed using pre-formed MDF skins that are pressed with a decorative panel design, then bonded to a door core (hollow, solid). These skins are made using high-pressure molds that shape the surface to resemble classic door styles—like 2-panel, 6-panel, or Shaker designs.

Why It’s Called “Imitation” Shaker

While the panel design resembles the clean, rectangular style of a Shaker door, the appearance is formed by pressing the skin, not by assembling real rails and stiles.

Most importantly:

Because of the molding process, the edges of the panels cannot achieve a sharp 90° angle like true Shaker doors.

Instead, they typically have a slightly curved or softened bevel, making it a visual imitation, not a true Shaker construction.

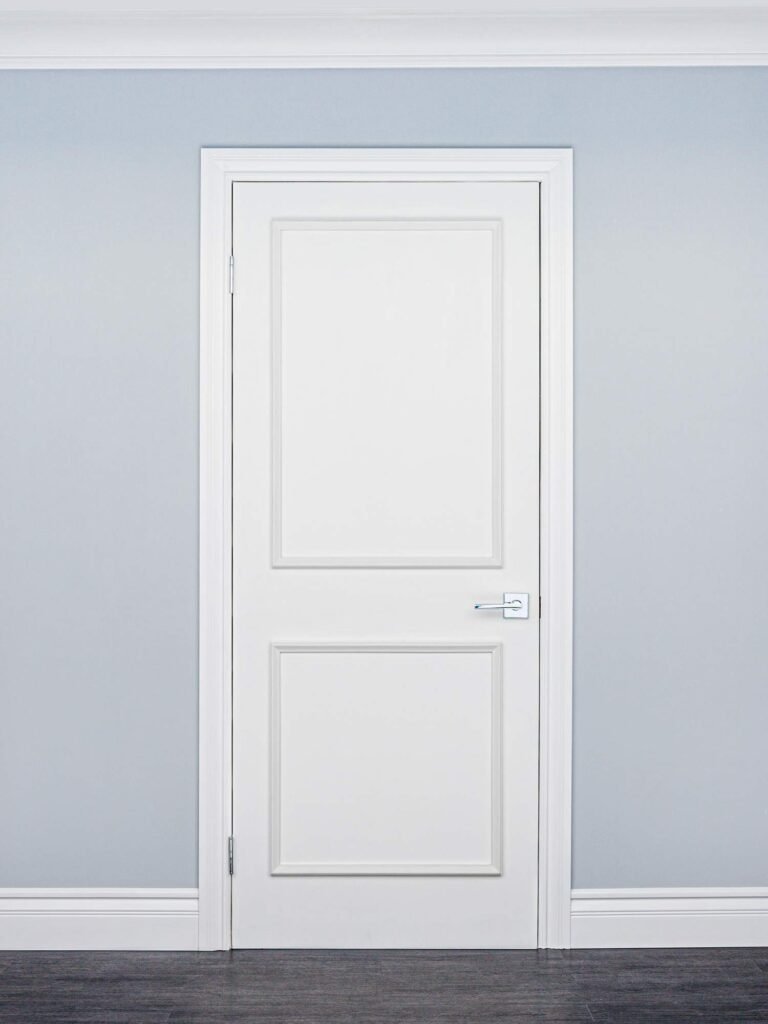

What Is Considered a Shaker Door?

Shaker doors are one of the most iconic and widely used cabinet and interior door styles in both residential and commercial builds. But what exactly qualifies a door as “Shaker”?

At its core, a Shaker door is defined by its five-piece construction: four flat frame pieces (two stiles and two rails) forming a rectangular border, with a recessed center panel. The lines are clean, simple, and symmetrical.

Builders love Shaker doors for their structural integrity, while designers favor them for their versatility — easily painted, stained, or left natural.

Key characteristics of true Shaker doors:

- 5-piece frame with recessed center panel

- Typically made from solid wood or plywood

- Clean, square-edged joints

Common Shaker Door Panel Configurations:

| Panel Style | Description | Common Uses |

|---|---|---|

| 1-Panel Shaker | A single large flat center panel with 4-square edge frame | Modern homes, minimalistic interiors |

| 2-Panel Shaker (equal) | Two vertically stacked flat panels with equal height | Traditional to transitional designs |

| 2-Panel Shaker (arch or combo) | One smaller top panel + larger bottom panel (rare) | Slightly decorative look |

| 3-Panel Shaker | Three vertical or horizontal panels | Hallways, utility rooms |

| 4-Panel Shaker | Four evenly divided rectangular panels | Classic residential use |

| 5-Panel Shaker | Five horizontal panels, narrow and evenly spaced | Common in Craftsman or farmhouse styles |

| 6-Panel Shaker | Six recessed panels, often 3 over 3 or 2 over 4 layout | More traditional, decorative doors |

For wholesalers and contractors, true Shaker doors deliver premium quality and long-term value, but they do come with a higher price tag compared to molded imitations — which we’ll discuss next.

How Do Shaker and Molded Doors Compare in Cost?

When it comes to cost, Shaker and molded doors differ significantly due to materials, manufacturing processes, and labor intensity.

Shaker Door Costs (Traditional Construction)

- Materials: Solid wood (like pine,oak, birch) or premium veneers

- Construction: True 5-piece assembly

- Wholesale price range: ~$80–$150+ per door

- Labor/finishing: Higher — often requires staining, sealing, or custom paint

These doors are best suited for higher-end builds, custom homes, or commercial projects where long-term durability and aesthetics matter.

Molded Door Costs (Limitation Shaker Molded)

- Materials: Molded HDF or MDF with embossed detail

- Construction: One-piece, lightweight core

- Wholesale price range: ~$30–$60 per door

- Labor/finishing: Often comes primed or prefinished, reducing on-site work

These doors are ideal for budget-conscious builds, multi-family units, or quick-turn projects where cost and speed outweigh luxury.

Pro Tip: If your project is price-sensitive — think apartments or rentals — molded doors offer serious savings. But for clients demanding long-term quality, go with real Shaker.

| Feature | Shaker Doors | Shaker Style Molded Doors |

|---|---|---|

| Material | Solid wood / plywood | Molded HDF / MDF |

| Construction | 5-piece assembly | One-piece molded skin |

| Price Range | ~$80–$150+ | ~$30–$60 |

| Finishing | Often requires painting/staining | Usually pre-primed |

| Best For | High-end homes, long-term durability | Budget interiors, apartments, fast installs |

Shaker vs Molded: Which Is More Durable for Projects?

Durability is where the real difference between Shaker and molded doors becomes clear — especially in high-use areas like kitchens, rentals, or commercial spaces.

Shaker Doors: Built to Last

Made from solid hardwoods or plywood, Shaker doors are built to handle:

- Impact and dent resistance

- Humidity and temperature shifts

They can also be easily repaired if a panel or stile gets damaged.

Molded Doors: Durable Enough — to a Point

Molded doors use compressed MDF or HDF, which keeps costs low but introduces trade-offs:

- More prone to surface dents and edge chips

- Not ideal for high-moisture areas (unless sealed well)

Builder Tip: Match door type to environment. Use molded doors for budget interiors, and true Shaker where style, strength, and resale matter most.

Should Builders Choose Molded Shaker Doors for Large Projects?

Yes — molded Shaker doors are a smart choice for large-scale builds when balanced with practical expectations.

Why They Work:

- Cost Savings: Molded doors are about half the cost of traditional Shaker.

- Faster Install: Primed, lightweight, and easy to hang.

- Logistics Friendly: Less weight = lower freight costs.

When to Think Twice:

- Wet areas: Molded fiberboard can swell or degrade over time.

- Luxury projects: Solid wood is expected in high-end homes.

- Heavy use zones: Molded doors are more likely to show wear.

“Use molded Shaker doors when scalability, simplicity, and affordability matter more than longevity or authenticity.”

They’re perfect for apartment builds, residential flips, and mid-range communities needing speed and visual appeal — without sacrificing budget.

Shaker doors: Durable, repairable, resistant to impact, dents, and humidity

Shaker style molded doors: Adequate for normal use, more prone to dents and edge chips; avoid high-moisture areas

Summary

Choosing between real Shaker doors and molded alternatives depends on your project goals. Know the build, the budget, and the style needs — then make a smart, informed decision. Got questions? Let’s feel free to contact me!!