When you step into a room, have you ever noticed the subtle yet impactful details that elevate its elegance and charm? Among these often-overlooked elements are the mouldings that frame the walls, ceilings, and floors. These architectural features might seem simple at first glance, but they play a crucial role in defining the character and style of a space. Have you ever wondered how these mouldings, especially those with a perfectly smooth, primed finish ready for painting, are actually made?

The process of making primed wood mouldings is a fascinating blend of traditional craftsmanship and modern technology. Each step is meticulously designed to ensure that the final product is not only durable but also aesthetically pleasing. From selecting the finest materials to applying the primer with precision, every detail contributes to creating a moulding that is both attractive and ready for easy installation. For wholesalers and builders, understanding this process offers valuable insight into the quality and value of the products they use and sell, making it easier to appreciate the craftsmanship behind these essential architectural details.

- What Materials Are Used to Make Primed Wood Mouldings?

- How Is the Wood Prepared for Moulding Production?

- What Techniques Are Involved in Shaping the Mouldings?

- How Is the Primer Applied to the Mouldings?

- What Are the Quality Control Steps in the Production Process?

- How Are Primed Wood Mouldings Packaged and Shipped to Customers?

- Conclusion

What Materials Are Used to Make Primed Wood Mouldings?

The foundation of any high-quality moulding is the material from which it’s made. Primed wood mouldings typically start with either solid wood or medium-density fiberboard (MDF). Solid wood, such as pine, oak, or poplar, is chosen for its natural grain and strength, making it ideal for projects requiring a more traditional or luxurious look. MDF, on the other hand, is a composite material made from wood fibers and resin. It’s prized for its smooth surface and uniformity, which makes it an excellent choice for primed mouldings that will be painted. The choice of material often depends on the specific needs of the project, with considerations for cost, durability, and the desired final appearance.

How Is the Wood Prepared for Moulding Production?

Once the material is selected, the preparation process begins. For solid wood, this involves carefully drying the lumber to the correct moisture content to prevent warping or cracking later on. The wood is then planed to create a smooth, even surface. MDF requires a different approach, as it is already smooth and flat. However, it is often cut to size and sanded to ensure that there are no imperfections before moving to the next stage. In both cases, the goal is to start with a flawless base that will lead to a high-quality finished product.

What Techniques Are Involved in Shaping the Mouldings?

Shaping the wood into the desired moulding profile is a critical step in the process. This is typically done using specialized milling machines that can create a variety of intricate shapes and designs. The wood or MDF is fed through the machine, where rotating knives carve the material into the desired profile. The precision of this process is key, as even a slight deviation can ruin the moulding’s appearance. For more complex designs, multiple passes may be required to achieve the final shape. The result is a beautifully detailed moulding that is ready for priming.

How Is the Primer Applied to the Mouldings?

Applying primer to wood mouldings is a crucial step that prepares the surface for painting and protects the material from moisture and other environmental factors. The mouldings are typically sprayed with a high-quality primer, which is evenly applied to ensure complete coverage. This may involve multiple coats, with each one being carefully dried and sanded between applications to achieve a smooth, even finish. For MDF mouldings, special care is taken to seal the edges, which can be more porous than the surface. The result is a primed moulding that is smooth to the touch and ready to accept any paint color, ensuring a professional-looking finish in the final installation.

What Are the Quality Control Steps in the Production Process?

Quality control is an integral part of the moulding production process, ensuring that each piece meets the high standards expected by wholesalers and builders. After shaping and priming, each moulding undergoes a thorough inspection to check for any defects, such as warping, cracks, or uneven primer application. Automated systems and experienced workers collaborate in this process, using both visual inspections and precision measuring tools. Any moulding that doesn’t meet the required standards is either reworked or discarded. This rigorous quality control ensures that only the best products make it to the packaging stage.

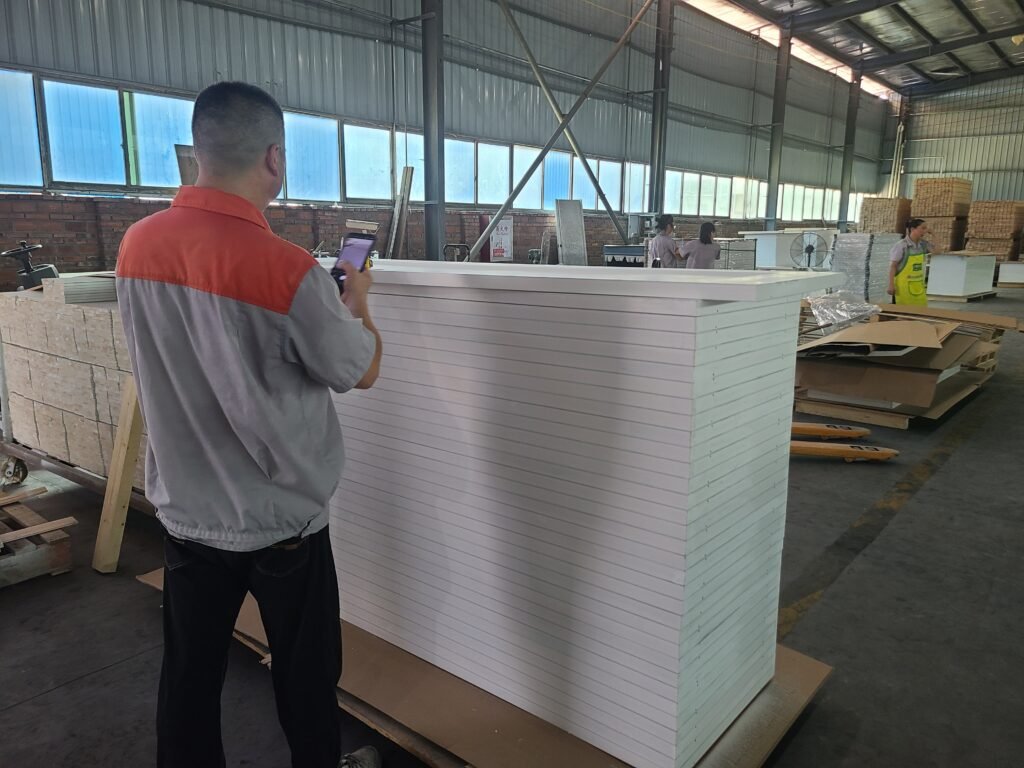

How Are Primed Wood Mouldings Packaged and Shipped to Customers?

Once the mouldings have passed quality control, they are ready for packaging and shipment. Proper packaging is essential to protect the mouldings from damage during transit. The mouldings are carefully wrapped, often in protective plastic or cardboard, and then bundled together in manageable quantities. For larger orders, the bundles are placed on pallets and secured to prevent movement during shipping. Attention to detail during this final stage ensures that the mouldings arrive at their destination in perfect condition, ready to be installed and painted by the customer.

Conclusion

The process of making primed wood mouldings is a blend of art and science, requiring precision at every step. From selecting the right materials to ensuring the final product meets rigorous quality standards, each stage is designed to produce mouldings that are not only functional but also aesthetically pleasing. For wholesalers and builders, understanding this process underscores the value of choosing high-quality, expertly crafted mouldings for their projects. Whether it’s the intricate shaping or the flawless priming, each detail contributes to the overall beauty and durability of the finished product, making it an essential element in any building project.