You’re planning a big renovation project or preparing inventory for your next bulk sale. The finish line is clear—except for one thing: mouldings. Order too fast, and you risk warped pieces, mismatched sizes, or late shipments. Before committing to bulk quantities, a few smart checks can save you a costly headache. Let’s break down everything you must check before confirming that order.

Before bulk ordering mouldings, check for material quality, supplier reliability, moisture content, dimensions, finish consistency, and whether samples are available. Confirm lead times, return policies, and price breaks. Evaluate MDF vs. wood options based on project needs. For large orders, always request technical specifications and ensure the supplier can meet your volume without delays.

Let’s dive into the essential questions every contractor, builder, or wholesaler should ask before clicking “Order.”

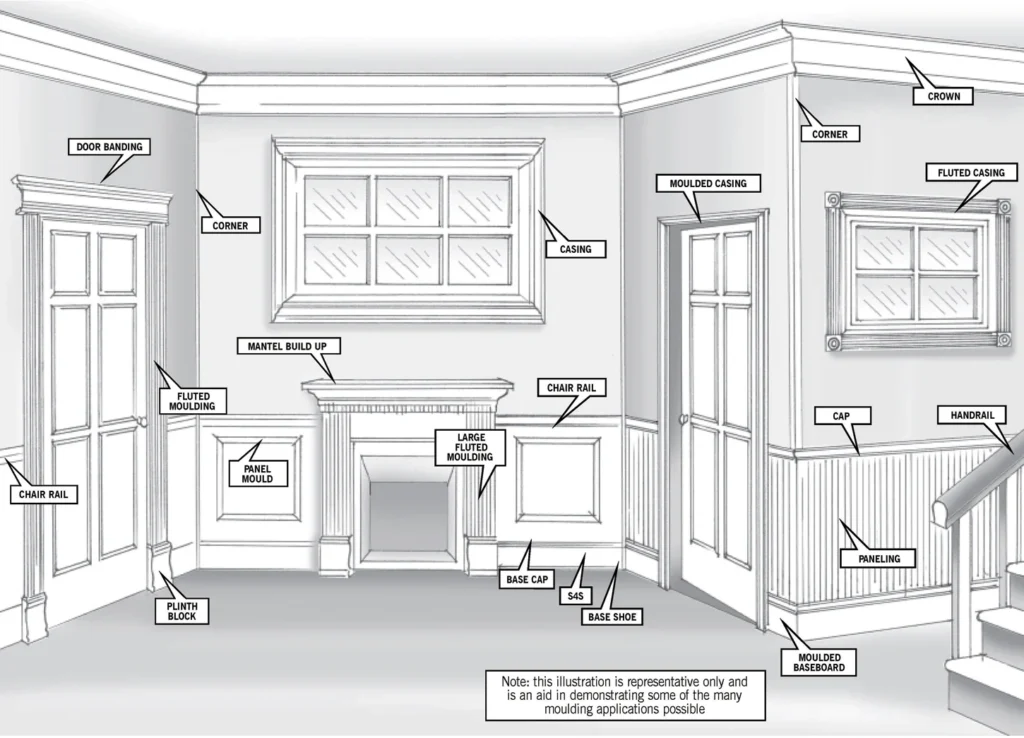

What are the different types of moulding?

When considering moulding for bulk orders, it’s crucial to understand the different profiles available. Here’s a detailed breakdown of the main types used in construction and renovation projects:

- Baseboard Moulding: Baseboard moulding, also known as base trim, is typically installed along the bottom of walls. It protects the wall from damage and provides a clean, finished look. Available in various heights and styles, baseboards are commonly made of wood, MDF.

- Crown Moulding: Installed where the walls meet the ceiling, crown moulding adds elegance to any room. From subtle curves to intricate carvings, the design options for crown moulding are vast.

- Chair Rail Moulding: Positioned halfway up a wall, chair rail moulding prevents damage from furniture like chairs or tables. It also helps define a room’s design by breaking up wall color and adding a more sophisticated appearance.

- Casing Moulding: Casing refers to the trim around doors and windows. It provides a finished look and can be simple or decorative, depending on the style of the home.

- Panel Moulding: Often used for wainscoting or creating framed panels on walls, panel moulding is a more decorative profile. It’s often installed in dining rooms or hallways, giving the space a timeless, formal appearance.

For bulk orders, understanding the purpose of each type will guide you toward the best choice for the project. Keep in mind that baseboard and casing moulding are more common for general use, while crown and chair rails are reserved for specific, high-traffic areas or decorative applications.

How do I choose the right moulding?

Selecting the right moulding involves considering multiple factors to ensure both aesthetic appeal and durability. Here are some in-depth tips:

- Room Style and Design: Consider the overall design of the room or building. For contemporary spaces, sleek, simple profiles may be best, while traditional or Victorian-style rooms benefit from more intricate, detailed mouldings. Look at the furniture, flooring, and other elements of the room to choose moulding that complements the existing design.

- Material Considerations: Moulding can be made from a variety of materials, each with its own pros and cons:

- Wood: High-end, durable, and attractive. Wood is ideal for visible areas like living rooms or dining rooms.

- MDF: Medium-density fibreboard is an affordable option and ideal for those on a budget. It can be painted easily but may not hold up in areas with high moisture.

- Functionality and Durability: Think about how the moulding will be used. For example, baseboards will endure foot traffic and potential scuffs, so a tougher material like wood or a high-density MDF is preferred.

- Finish Requirements: Some materials, like MDF, require primed or painted , while wood can be stained or left natural. Consider the amount of maintenance the moulding will require over time. Wood will need occasional refinishing, while MDF might require touch-ups if it’s heavily used.

By assessing these aspects, you’ll be able to make a more informed decision that fits the needs of your project, ensuring a balance between functionality, style, and cost-effectiveness.

How is moulding priced?

Understanding the pricing structure of mouldings is vital for builders, contractors, and wholesalers. Here’s an expanded explanation of what affects moulding prices:

- Material: The material significantly affects the cost. MDF is typically the least expensive, making it ideal for larger projects or budget-conscious buyers. Wood, usually radiate pine, is more expensive.

- Design Complexity: Intricate, custom profiles—like ornate crown moulding—can command higher prices than simple, straight-edged baseboards. The time and machinery required to make more complex designs add to the overall cost.

- Size and Dimensions: Larger profiles (e.g., for crown moulding) or longer lengths (e.g., baseboards over 12 feet) will increase the cost of the moulding per unit.

- Bulk Discounts: Many suppliers offer price breaks when you order in large quantities, typically starting at 5000 feet or more. These discounts may vary by material, so make sure to ask the supplier about their bulk pricing tiers.

- Shipping Costs: Large orders can increase the shipping cost, especially if the moulding is heavy or oversized. Some suppliers offer discounted shipping for bulk orders, so be sure to factor in these expenses when comparing prices.

What are the pros and cons of MDF vs. wood mouldings for bulk orders?

For builders and contractors, deciding between MDF and wood mouldings for bulk purchases depends on budget, project requirements, and long-term goals.

MDF Moulding

- Pros:

- Affordable: Perfect for budget-conscious projects.

- Smooth finish: Takes paint well, offering a uniform look without visible seams.

- Consistent quality: Unlike wood, MDF doesn’t have natural imperfections, making it ideal for a clean finish.

- Cons:

- Not suitable for high-moisture areas: It can warp or swell in environments like bathrooms or kitchens.

- Less durable: MDF is softer than wood, meaning it’s more susceptible to dings and damage.

Wood Moulding

- Pros:

- Durable and long-lasting: Wood is the most durable option, making it ideal for high-traffic areas.

- Natural look: Wood has a natural grain and texture that can’t be replicated by MDF, adding beauty and value to a home.

- Moisture resistance: Some types of wood, like oak or pine, are naturally more moisture-resistant than MDF.

- Cons:

- Expensive: High-quality wood can be much more expensive than MDF.

- More maintenance: Wood requires more upkeep, including sanding, staining, or refinishing over time.

Understanding these pros and cons will help you decide which material best suits your needs for large-scale projects.

Should I request moulding samples before placing a large order?

Absolutely! Here’s why you should request samples before making a bulk purchase:

- Ensures Quality: Physical samples allow you to examine the finish, texture, and material firsthand. This reduces the chances of receiving faulty or damaged items in a large order.

- Accuracy: Samples allow you to check the fit and aesthetic against existing elements in your project (walls, furniture, etc.). This ensures the moulding matches the space in terms of design and dimensions.

- Ease of Comparison: If you’re torn between two materials or styles, seeing them side-by-side gives you clarity.

What quality checks are important before bulk ordering mouldings?

Before making a bulk order, you should conduct several quality checks to ensure the moulding meets your standards. These checks will save you time and money by preventing issues down the line:

- Dimensions: Moulding pieces should be measured accurately, especially for bulk orders where consistency is key. Ensure the thickness and length align with the project’s requirements.

- Finish Consistency: Look for smooth surfaces free of visible defects. If the moulding is pre-finished, check for paint drips, gaps, or uneven color application.

- Moisture Content: Particularly for wood moulding, ensure the moisture content is appropriate. Too much moisture can lead to warping and dimensional instability. Suppliers should provide data on moisture levels.

- Packaging: Check that the moulding is properly packaged to prevent shipping damage. Bulk orders should be packed in sturdy, protective packaging to minimize the risk of dents, chips, or scratches.

How to evaluate moulding suppliers for reliability and delivery times?

When placing a bulk order, it’s essential to evaluate your suppliers to ensure they are reliable and can meet your needs:

- Supplier History: Check their reputation by looking at customer reviews, industry ratings, and any feedback from previous bulk orders.

- Lead Times: Confirm the lead time on bulk orders, especially if the moulding is custom or requires special finishing. Suppliers should give you an estimated delivery time and stick to it.

- Customer Support: Reliable suppliers offer responsive customer support in case issues arise during the order process. Check their responsiveness to inquiries and order confirmations.

- Shipping: Make sure they can meet the agreed shipping deadlines and that their delivery methods are cost-effective for bulk shipments.

Purchase Suggestions

Before finalizing your order:

- Request written quotes and lead times

- Ask for samples of each type and finish

- Clarify freight and handling charges

- Confirm MOQ and overage policies

A good supplier will help you simplify logistics while reducing product waste.

Summary

Ordering mouldings in bulk doesn’t need to be risky. By checking product specs, verifying suppliers, and understanding materials, you’ll ensure every piece fits the job. Have a tip or question? Share it with us!