Choosing the right kitchen cabinet source impacts not just aesthetics—but also cost control, labor efficiency, and delivery timelines. For builders and wholesalers managing scaled residential or commercial projects, factory-made kitchen cabinets provide a faster, more consistent, and more economical path forward.

But where do you find the right factory partner that understands project timelines, handles mixed SKUs, and delivers quality at volume?

Factory-made kitchen cabinets deliver consistent quality, faster installation, and better cost control. Manufacturers like UWG provide end-to-end service—design, production, and delivery—customized for wholesale and builder-scale projects. For professionals, the right cabinet partner simplifies builds and improves project profitability.

Let’s look at how factory-made cabinets compare to traditional methods, and how UWG helps builders streamline their supply chain.

What Are Factory-Made Kitchen Cabinets?

Factory-made kitchen cabinets are produced using standardized industrial processes—designed for scale, speed, and quality consistency. Unlike on-site carpentry or third-party workshops, these cabinets are manufactured under controlled factory conditions using:

- CNC cutting for panel accuracy within ±0.2mm

- Edge banding and hot melt adhesives for long-lasting joint durability

- Modular box construction, ideal for repeatable installations

- Machine-drilled dowel and cam lock assembly, ensuring tight fit

- Consistent materials such as melamine-faced chipboard (MFC), plywood, or MDF

- Automated quality control to detect defects before shipment

These cabinets are engineered with project efficiency in mind—designed to work with standardized room layouts, local building codes, and common appliance footprints.

For builders and wholesalers, factory cabinets help:

- ✅ Eliminate unpredictable on-site woodwork

- ✅ Speed up project delivery with off-the-shelf SKUs

- ✅ Reduce dependence on skilled carpenters

- ✅ Minimize rework, warping, and installation errors

- ✅ Ensure color, finish, and hardware consistency across 50+ units

- ✅ Improve cost forecasting and margin control

Most importantly, factory cabinets support repeatability—a must-have for multi-unit developments, hospitality projects, and design-build workflows.

The Formats: RTA vs Pre-Assembled vs Fully Built Cabinets

Understanding cabinet formats is essential for planning logistics, labor, and site coordination. At UWG, we manufacture all three major formats, each serving different project needs:

| Cabinet Type | Description | Ideal For |

|---|---|---|

| RTA (Flat Pack) | Cabinets are shipped flat-packed with hardware and instructions included. | Export markets, DIY clients, warehouse stock |

| Pre-Assembled | Cabinets are assembled at factory, ready for direct installation. | Urban job sites, fast installs, limited labor |

| Fully Built | Cabinets are pre-finished and pre-assembled with doors, drawers, and trims. | Luxury projects, hospitality, show units |

🧱 Key Differences by Format:

- Shipping Efficiency:

- RTA: Maximizes pallet loading capacity (up to 150 units/container)

- Pre-Assembled: Lower shipping density but saves site time

- Fully Built: Requires protective packaging, higher freight cost

- Labor Requirement:

- RTA: Requires 15–25 minutes/unit for skilled installers

- Pre-Assembled: Off-truck to install in under 5 minutes

- Fully Built: Minimal site work, plug-and-play setup

- Damage Risk:

- RTA: Flat-packed reduces transit damage

- Pre-Assembled: Requires careful stacking

- Fully Built: Heavier packaging, higher risk if mishandled

At UWG, all cabinet formats are produced with project-based flexibility:

- Ship RTA for cost-effective freight

- Request pre-assembly for urgent project timelines

- Mix formats in one order (e.g., RTA base + assembled uppers)

We tailor your container loading based on delivery method, warehouse space, and install crew size—ensuring maximum site efficiency.

Where to Buy Factory-Made Cabinets Online?

For builders and wholesalers managing time-bound, multi-unit construction, traditional cabinet procurement often leads to logistical bottlenecks and budget overruns.

You might relate to these common pain points:

- ❌ Unmatched styles or inconsistent colors when sourcing from multiple resellers

- ❌ No layout service—your team is left measuring and matching blindly

- ❌ Freight, customs, and paperwork are your responsibility, not theirs

- ❌ Retail-grade cabinets lack durability for high-traffic or moisture-prone installations

- ❌ No post-sale technical support, especially on multi-SKU orders

While big-box stores or RTA eCommerce platforms cater to DIY homeowners, their service models don’t scale for developers, GCs, or building material distributors.

That’s why builders are moving upstream—partnering directly with vertically integrated manufacturers like UWG (United Woods Group), who offer design-to-delivery cabinetry built specifically for commercial and wholesale needs.

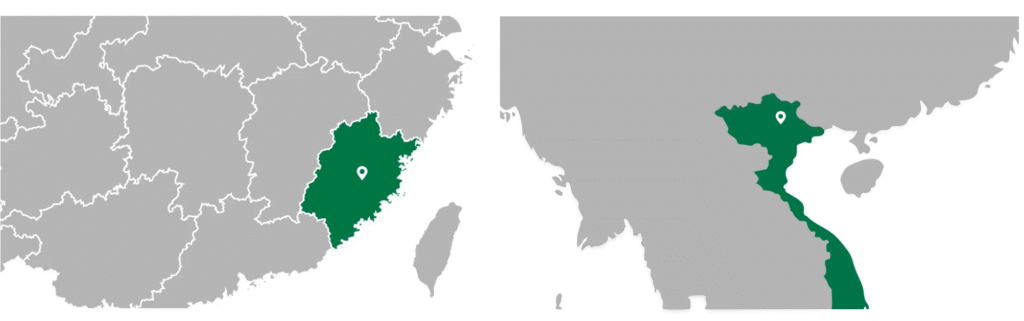

UWG operates across China, Vietnam, and the United States, providing factory-direct cabinets, doors, flooring, and millwork in one streamlined supply chain.

Why Builders & Wholesalers Choose UWG

When price, speed, and scale must work together, UWG becomes more than a supplier—we become your backend production partner.

🏗️ Designed for Project-Scale Fulfillment

- Annual Capacity: Over 1,000 containers/year, ensuring production continuity

- Factory Area: 30+ acres of floor space with automated lines and QC zones

- Dedicated Cabinet Facilities: In Zhejiang (China) and Phú Thọ (Vietnam), with U.S. processing support

Whether you’re outfitting 200 units or handling phased deliveries across job sites, UWG can build to your demand.

🚛 Global Delivery with Full Support

- RTA, pre-assembled, or fully built formats available

- Door-to-door shipping with documentation, labeling, and customs coordination

- Mixed product shipments (e.g., doors + cabinets + trim) packed per room/unit/SKU

- Processing Center in Oklahoma supports U.S.-based warehousing and fulfillment

We handle container optimization, freight booking, and arrival scheduling, so you stay focused on construction—not coordination.

🧰 Technical & Design Partnership

Your success starts at the layout stage. That’s why we provide:

- AutoCAD/SketchUp-compatible cabinet drawings

- 3D renderings and walkthrough-ready visuals upon request

- Style-matched recommendations based on project specs

- Ongoing technical support during install or reordering

Think of us as your remote design desk—backed by a full production line.

💲 Transparent, Factory-Direct Pricing

- Fixed pricing unaffected by freight fluctuation or short-term tariff policy

- Factory cost savings of 30–50% compared to U.S. retail suppliers

- Long-term project pricing available for phased build-outs

No hidden charges. No upcharges for pre-assembly. No more surprises.

🧱 UWG Cabinet Styles at a Glance

Whether you’re supplying multifamily developments or luxury custom homes, we’ve got the finishes and formats you need:

- Shaker: Clean lines, universal appeal, fastest-moving SKU in mid-range housing

- Flat Panel: Minimalist look, ideal for urban or modular builds

- Raised Panel: Traditional charm, upscale project compatibility

- Custom Orders: Unique veneers, colors, handle pre-routing, finish gloss levels

Each program includes coordinated moldings, toe kicks, side panels, and fillers, all packaged by unit plan to simplify installation.

If your crew can unpack it, they can install it. We’ve engineered our cabinet system to align with real-life jobsite conditions.

How UWG Works with Builders

We understand that builders, general contractors, and developers need more than a catalog—they need a reliable process from proposal to project handover.

Here’s how our streamlined 4-step model supports your entire cabinet sourcing workflow:

1. Design Proposal

- Submit your floor plans, cabinet list, or even a simple sketch

- We return a full design package including:

- 2D layouts

- 3D renderings for client approvals

- Complete BOM (Bill of Materials) with SKUs and quantities

Whether it’s a single-family home or a 500-unit complex, we design around your specs and site limitations.

2. Sampling & Approval

- We ship color swatches, material samples, or trial cabinet sets

- You approve:

- Style & finish

- Hardware spec

- Assembly level (RTA or pre-assembled)

Want custom colors or handle pre-routing? We lock it in here—so mass production starts right.

3. Mass Production

- Standard lead time: 30–45 days

- High-capacity CNC and line production enable volume scaling per project phase

- Consistent output across phases or repeat orders—ideal for phased builds

4. Delivery

- Packed by unit, room, or SKU based on your install sequence

- Mixed product shipments (cabinets, doors, flooring) allowed

- Shipping available with DDP terms (Delivered Duty Paid) for seamless imports

🎯 Think of UWG as your outsourced cabinet department—without the overhead, risk, or coordination burden.

What to Look for in a Cabinet Manufacturer

A reliable B2B cabinetry partner should do more than manufacture boxes. Ask yourself:

✅ Can they meet multi-project timelines? Not just production speed—but phasing, volume ramp-up, and repeatable quality.

✅ Can they consolidate SKUs in one shipment? Avoid dealing with multiple suppliers, customs agents, and freight forwarders.

✅ Do they offer layout design and spec verification? Not just “send the product”—you want partner-grade documentation support.

✅ Do they understand jobsite constraints and installer realities? We’ve seen warped doors, mismatched panels, missing filler strips—and built systems to prevent that.

With UWG, you get all of this and more:

📦 Manufacturing scale + 🧩 Design support + 🚛 Shipping precision = Less stress, fewer delays, better results.

Conclusion

The shift toward factory-made cabinetry is more than a trend—it’s a transformation in how modern construction teams manage time, risk, and budget.

But not all suppliers are created equal.

We combine scalable manufacturing, value-engineered materials, pre-install labeling, and complete logistics management to support your team from first drawing to final walkthrough