The global building materials industry is full of hidden costs. Middlemen, distributors, showrooms, and logistics layers all add markups — and you, the buyer, end up paying for them. Whether you’re a contractor, wholesaler, or even a homeowner managing your own renovation, the price you see on a retail invoice is rarely the true cost of the product.🧐 So where exactly does all that extra money go?

Buying directly from the factory cuts out multiple layers of distribution and logistics costs. With no distributors, no showrooms, no middle agents, you access the ex-factory price — often saving 30–50% compared to traditional supply chains. Combined with streamlined communication, direct accountability, and flexible customization, it’s the smartest way to buy building products today.

Where Does the 30–50% Go?

In a typical retail or construction procurement pipeline, a single product changes hands multiple times before it ever reaches the jobsite or showroom floor. Each step adds margin:

Manufacturer ➝Export agent ➝National distributor ➝Regional wholesaler ➝Local retailer ➝End user

Each link may add 10–25% to the base cost. By the time the product hits the retail floor, the final price could be 2–3 times the ex-factory cost.

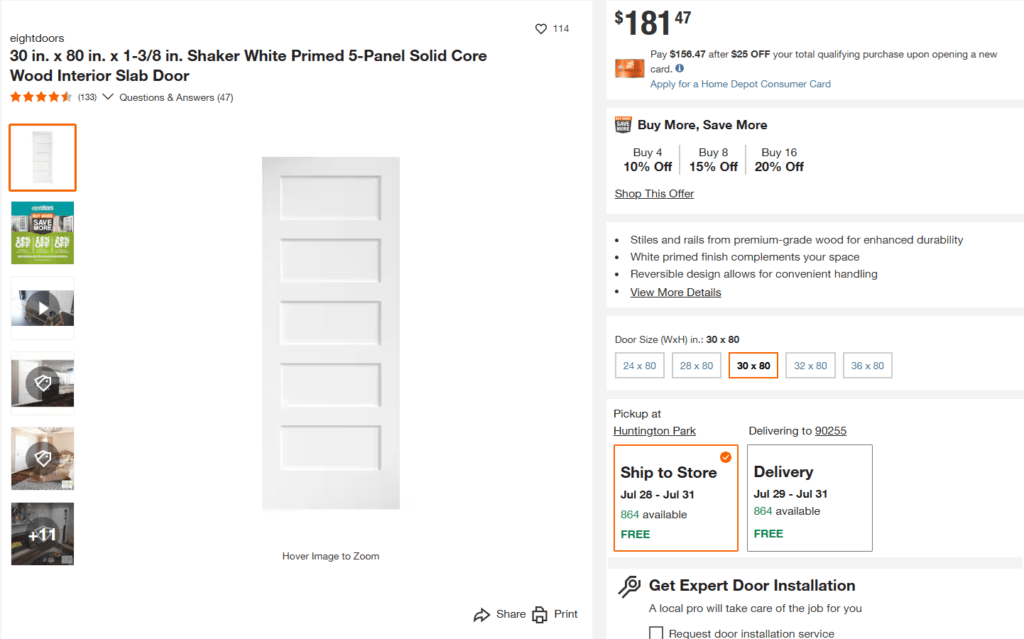

- 30 in. x 80 in. x 1-3/8 in. Shaker White Primed 5-Panel Solid Core Wood Interior Slab Door. This door on Home Depot is priced at $181.47:

Our factory door to door price is only half of that.

Multiply that by dozens or hundreds of units on a project, and the price difference becomes massive. With factory-direct, you receive the same product at origin pricing — saving you 30–50% instantly. The bigger the volume, the bigger the savings.

What to Watch Out for When Buying Direct?

While the factory-direct model is powerful, not all suppliers are built to deliver consistent quality and global service. Buyers should be aware of common risks:

- Lack of product certifications

- Poor communication or unclear lead times

- Low MOQ factories that outsource production rather than control it

We recommend always working with a factory that offers:

✅ Full product documentation

✅ Complete certifications.

✅ Consolidated shipping and logistics capabilities

Direct is only better if it’s dependable.

Our Factory Advantages

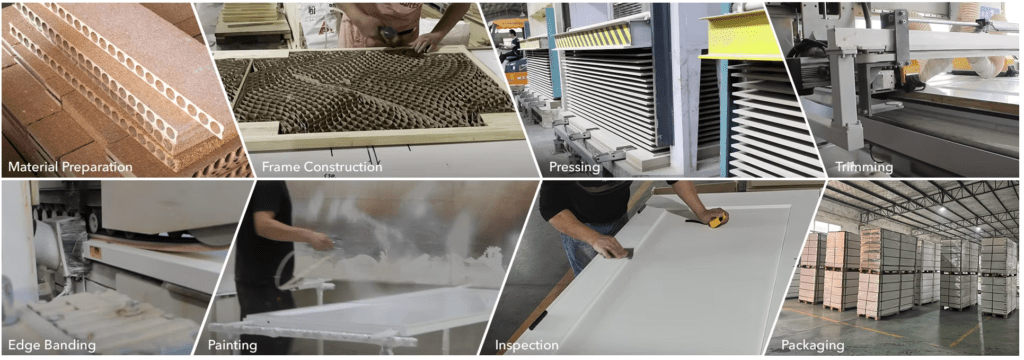

Not all factories are created equal. While the idea of “buying direct” sounds appealing, the value it delivers depends entirely on the capability of the supplier. Our factory isn’t just a manufacturer — we’re a full-spectrum production and logistics partner trusted by clients across North America, Oceania, and Europe.

We operate over 30 acres of modern manufacturing space with a dedicated team of more than 600 production staff. Our annual output exceeds 1,000 containers (40HQ), covering a wide range of building materials including interior and exterior doors, cabinets, flooring, mouldings, and millwork. That means clients can consolidate multiple product lines into a single order — saving time, freight, and administrative hassle.

From a procurement standpoint, our factory-direct pricing structure typically saves clients 30–50% compared to local wholesale costs, depending on order scale. We eliminate multi-layered markups by integrating production, sourcing, and shipping into one transparent pricing model. Even in volatile markets with fluctuating tariffs or freight surcharges, our clients benefit from fixed pricing and clear documentation — no surprises, no hidden charges.

But low price is only meaningful when backed by consistent quality. Our facilities are structured for in-house quality control, managing over 10,000 cubic meters of raw wood inventory sourced globally. We are particularly skilled at working with different wood species — from engineered materials to premium lumber — and can deliver products tailored to U.S. retail standards and commercial code requirements. If any product arrives damaged or fails to install as specified, we make it right — no negotiation needed.

Another key strength is door-to-door logistics handling. We manage everything from production scheduling to customs clearance, freight booking, and final-mile delivery. Our clients don’t need to hire a separate freight forwarder or coordinate with port agents — they simply receive, inspect, and install. This full-service model is especially valuable for contractors and project developers working on tight timelines and fixed budgets.

Unlike many specialized factories that only handle a single category, we offer product bundling. Doors, cabinets, flooring, mouldings — everything can be shipped in a single consolidated container. This drastically reduces shipping complexity, consolidates paperwork, and minimizes customs risk.

Finally, our technical support is one of the most frequently praised aspects of our operation. We provide layout drawings, cabinet design support, 3D renderings, and installation guidance for every product line. Whether you’re a seasoned builder or a first-time importer, our in-house design and engineering teams are here to help at every step — from concept to completion.

In short, what sets us apart isn’t just our price — it’s our reliability, our flexibility, and our deep understanding of what construction professionals actually need. That’s the real value of factory-direct sourcing done right.

Who Benefits Most from Factory-Direct Buying?

Factory-direct isn’t just for mega importers. In fact, it’s ideal for:

- Retailers or e-commerce sellers who want better margins and SKU control

- Construction contractors and developers managing multi-unit projects

- Homeowners and designers sourcing for renovation or new builds

- New brands looking to OEM/ODM private label their product lines

The more control you want over pricing, lead times, packaging, or specification — the more value direct sourcing brings to the table.

Conclusion

If you’re still buying through layers of agents, distributors, and branded resellers, chances are you’re paying far more than you need to — for the exact same product.

🏗️ Factory-direct means getting closer to the source, paying less, and gaining more control.

Whether you’re sourcing a single container or managing a full portfolio, choosing the right manufacturer partner is the first step toward long-term savings and supply chain peace of mind.

So, the real question is — are you ready to stop paying for someone else’s margin?