Builders are under constant pressure to reduce procurement costs while meeting high expectations from clients, inspectors, and project timelines. It’s tempting to switch suppliers based on lower quotes, assuming all materials are the same. But in reality, that switch often leads to delays, mismatched specs, communication breakdowns, and cost overruns. We’ve seen it time and again—after trying new suppliers, customers return to us. The question is: what makes them come back?

Let’s walk through why customers leave, what they experience elsewhere, and what brings them back to a partnership that actually works.

Why Do Customers Switch Suppliers in the First Place?

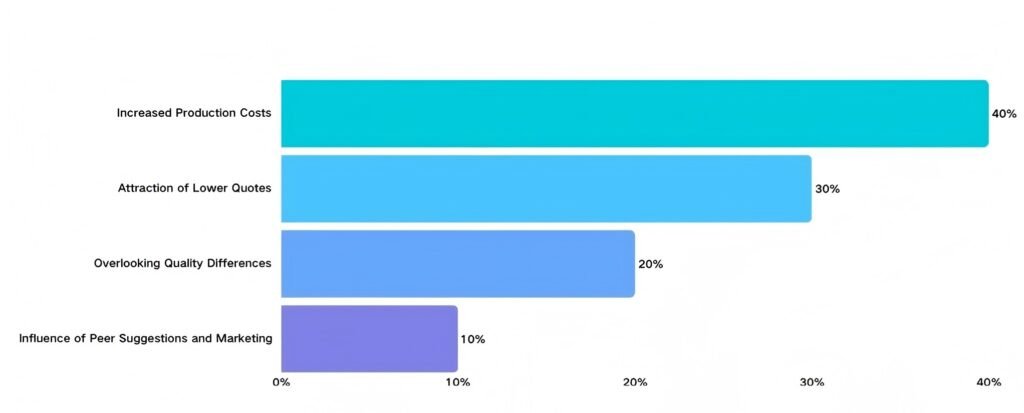

Builders don’t always leave a supplier because something went wrong—they often leave because of pressure. Rising project costs, volatile material prices, and client demands for faster timelines lead procurement teams to seek alternatives that seem “more affordable” or “more flexible.”

- Rising U.S. labor and production costs make domestic suppliers appear increasingly expensive, especially in categories like doors, cabinets, and flooring.

- New suppliers often advertise lower quotes, faster lead times, or bundled services that seem attractive—especially when procurement teams are measured on cost savings.

- Some builders assume, “Doors are doors,” or “Any cabinet will do,” believing that switching won’t impact installation or project quality.

The decision to switch is rarely about dissatisfaction—it’s often driven by hope. The hope that a cheaper supplier will deliver the same results for less. In some cases, this decision is also shaped by marketing, peer suggestions, or flashy online catalogs that don’t reflect real operational capabilities.

But here’s what gets overlooked: the real cost of switching. According to the Home Improvement Research Institute (2024), most contractors who switch suppliers do so due to perceived pricing gaps or declining service—not because of catastrophic failure. Yet many return after discovering that shipping delays, inconsistent quality, and lack of after-sales support quickly erode any initial savings.

Even The Farnsworth Group reports that while “90% of contractors report satisfaction when switching brands,” that satisfaction often fades when broader supplier functions—like logistics coordination, spec accuracy, or installation support—don’t meet expectations.

At first glance, switching seems logical. But as many returning customers admit later, they underestimated the full picture. They didn’t just need a cheaper quote—they needed a supplier who could deliver consistency, coordination, and confidence throughout the entire project cycle.What Happens After They Switch?

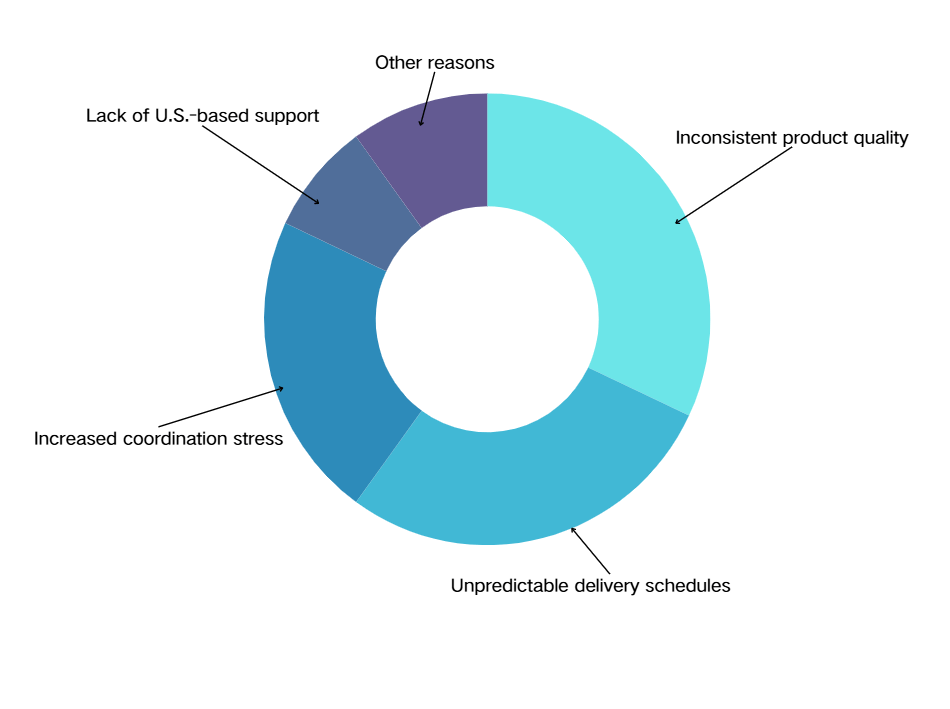

Soon after switching, many builders face the same set of problems:

- Inconsistent product quality from batch to batch—color mismatches, warping, or wrong specs.

- Unpredictable delivery schedules, often pushed back without warning.

- Increased coordination stress, dealing with multiple suppliers in different time zones.

- Lack of U.S.-based support—no one to help resolve on-site installation issues.

For example, a builder from Virginia ordered doors from a cheaper Southeast Asian factory. They received them 3 weeks late, and 40% of the doors didn’t match their architectural specs. Fixing that mistake cost them three weeks and thousands in labor.

What seemed like “savings” quickly became a loss—in time, budget, and client trust.

Why Do Customers Come Back to Us?

Customers don’t come back to us because they like to switch back and forth—they come back because they’ve experienced the alternative. After facing missed deadlines, poor communication, or products that didn’t meet spec, they realize that reliability, communication, and complete support are far more valuable than a short-term discount.

Our returning clients often tell us:

“We didn’t realize how much smoother everything was until we lost it.”

When they return, they’re no longer focused only on price—because they realize we already hold a comparative advantage in pricing. What truly sets us apart is our absolute strength in predictability, partnership, and peace of mind:

- End-to-end coordination from blueprint to container delivery—so there’s no guesswork

- Pre-approved samples to eliminate surprises and reduce jobsite errors

- One dedicated project manager who handles everything, not a rotating support line

- Factory-direct pricing that includes built-in logistics and U.S. installation options

- Local install crews who ensure everything fits, functions, and finishes perfectly

- A team that tracks timelines, adjusts production, and actively prevents problems before they happen

Case Example: A Florida-based builder switched to a new supplier to save on cabinet costs. But what followed was a chain of delays, mislabelled boxes, and uneven finishes. Their project was set back three weeks, and rework costs exceeded the initial “savings.” They returned to us for their next order—this time, we coordinated three product categories in one consolidated shipment, pre-approved all samples, and deployed a local team for installation. That builder is now under a rolling 12-month supply agreement with us.

We don’t just ship products—we build reliable, repeatable systems that work across multiple project types and regions. And once you’ve experienced that level of partnership, it’s hard to settle for anything less.

What Are the Hidden Switching Costs in Construction?

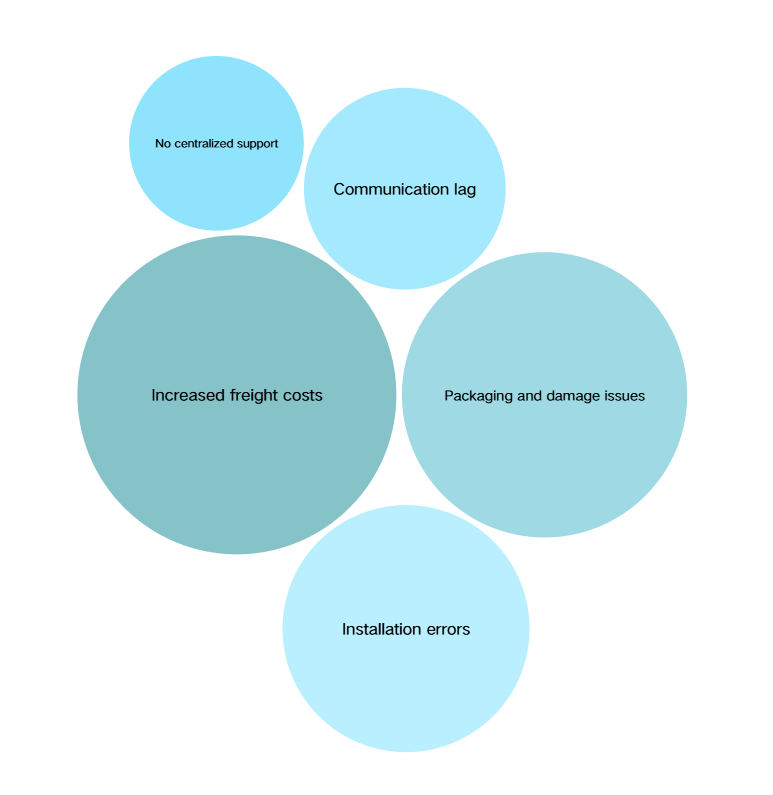

When evaluating a new supplier, many builders look only at the unit cost—but the most expensive mistakes are usually hidden in the supply chain.

Here’s where switching can quietly erode your budget, timeline, and client trust:

- Increased freight costs due to misaligned shipping schedules and lack of consolidation—leading to multiple partial loads instead of one efficient shipment

- Packaging and damage issues, especially with fragile components like cabinets, flooring, and mouldings that weren’t properly secured or labeled

- Installation errors caused by inaccurate specs, misaligned drilling patterns, or hardware incompatibility with U.S. standards—forcing rework or last-minute job site improvisation

- Communication lag across time zones that slows down approvals, problem-solving, and delivery coordination

- No centralized support, meaning the builder is left to coordinate between sales, production, and shipping teams—costing time, energy, and often delaying the next project phase

These issues don’t show up in the initial quote. They show up on the jobsite, when workers are idle, clients are calling, and delivery windows are missed.

That’s the true definition of switching costs—and in construction, they don’t just hurt your budget. They damage your reputation.

How We Help Rebuild Trust and Projects

When clients come back to us, they don’t just need a quote—they need help rebuilding control over a process that’s gone off track. That’s why our first step is never to blame, but to understand exactly what went wrong—and then fix it at the root.

We don’t just drop a container at your site and disappear. We rebuild trust by rebuilding the system behind your supply chain.

Here’s how we do it:

- Blueprint-to-factory matching, where our engineers review your plans line by line to ensure every spec, hinge, cutout, and finish is fully compatible with U.S. install practices. No more drilling on-site. No more “almost fits.”

- Sample verification, where nothing goes into production until you’ve seen, touched, and approved physical samples. This step alone saves our clients thousands in avoided rework.

- Local U.S. install teams, ready to support doors, cabinets, and flooring with experienced hands—not just to install, but to solve problems on the spot.

- Vietnam-based production, where we balance low-cost manufacturing with strict QC oversight, factory-direct control, and a resilient supply chain that protects against tariffs and shortages.

- Dedicated project coordinators, who know your project from Day 1 to final delivery. No ticket systems. No repeating yourself. One contact. One responsibility chain.

- 50% cost savings compared to U.S. retail pricing, without sacrificing quality or service. Because we manufacture for major retailers like Home Depot and Menards, but work directly with you—no markups, no middlemen, just factory-direct value.

When you work with us, you don’t just get materials—you get clarity, accountability, and execution. You get a partner who’s as invested in your project’s outcome as you are.

We remove the chaos. We remove the guesswork. We remove the burden of coordination—so you can get back to what you

do best: building.

Long-Term Supplier Relationships Beat Short-Term Deals

Procurement is more than purchasing—it’s about protecting your time, your margins, and your reputation. That’s why we don’t just offer products. We offer a partnership built for growth.

Builders who stay with us long-term don’t just save money—they avoid surprises, reduce overhead, and gain a smoother, more predictable project rhythm.

Here’s what makes that possible:

- Transparent pricing, with no hidden costs or moving targets—so you can quote your clients with confidence

- Unified product sourcing across doors, cabinets, flooring, trims, and more—one supplier, one shipment, one standard

- Stable material pipeline, even through trade fluctuations and global logistics shifts

- Integrated project support, from sample approval to on-site installation and warranty handling

- A vision beyond this order—we’re opening new offices in OKC to offer faster local support, while expanding into Europe and investing in smart automation to improve lead times and scalability

We’re not just solving today’s problems—we’re building tomorrow’s infrastructure.

And in an industry full of change, that’s what makes us different.

Because at the end of the day, what we deliver isn’t just materials. We deliver control, predictability, and peace of mind.

Conclusion

Switching suppliers may save pennies—but the wrong choice can cost weeks, damage trust, and stall entire projects. That’s why builders come back to us. Because in this industry, what truly wins isn’t the lowest price— It’s the partner who delivers consistency, clarity, and confidence—every single time.